Industrial Solar for Process Heat: Harnessing the Sun for Your Plant’s Thermal Needs

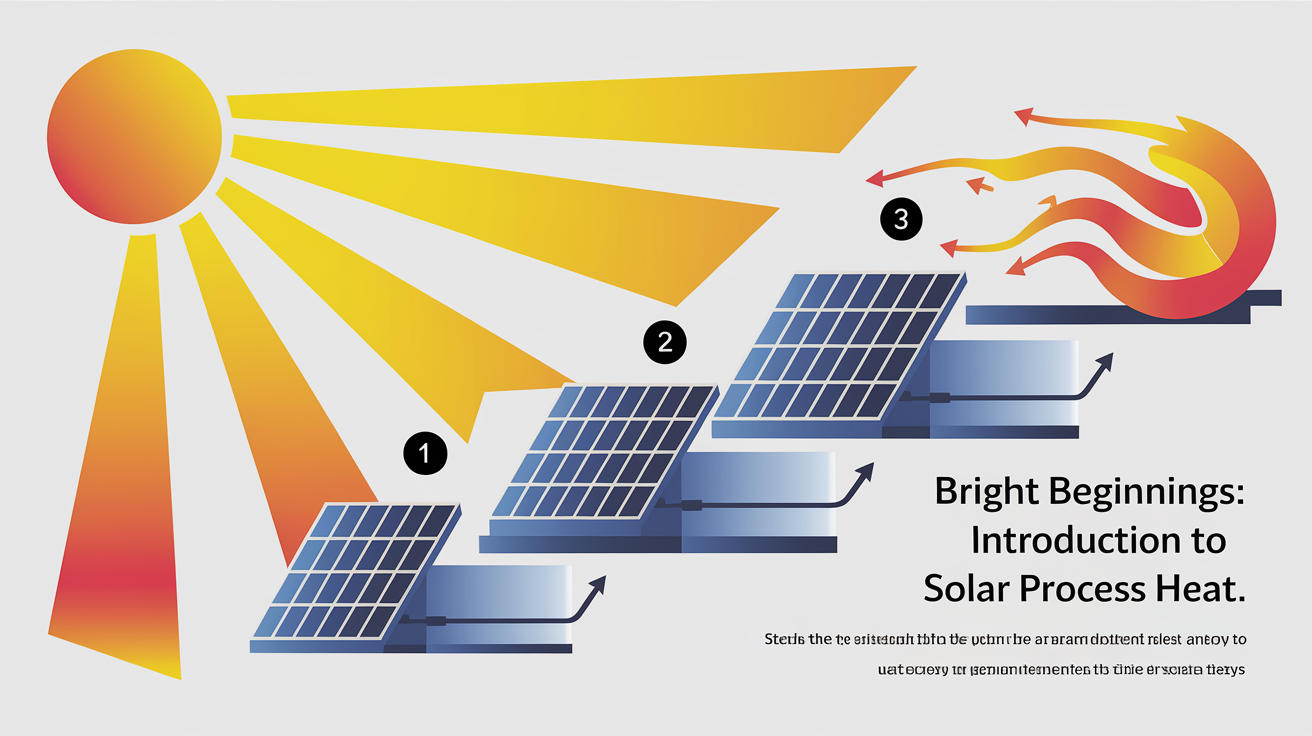

Bright Beginnings: Introduction to Solar Process Heat

Industrial manufacturing is undergoing a quiet revolution as facilities increasingly look to the sun for their thermal energy needs. Solar heat for industrial processes (SHIP) uses solar thermal systems to generate heat for applications such as drying, heating, cooling, and process steam generation. These systems range in capability from low-temperature (<80°C) tasks to high-temperature (>400°C) processes, leveraging technologies from flat plate collectors and evacuated tube collectors to concentrated solar power (CSP) devices like parabolic trough collectors and linear Fresnel systems.

By displacing fossil fuel-based heat production, SHIP can significantly reduce greenhouse gas emissions and help meet industrial decarbonization targets. According to the International Renewable Energy Agency (IRENA), solar heat integration represents a cornerstone of sustainable industrial energy strategies.

Assessing Solar Potential at Your Facility

Determining whether solar process heating is achievable requires a thorough assessment of a plant’s solar irradiance, thermal demand profile, and available space for collector arrays. Facilities can start by reviewing year-round solar field design considerations, including optimal orientation for thermal collectors and potential for rooftop or ground-mounted installations.

Key factors include:

- Annual direct and diffuse solar radiation levels

- Existing process heating equipment and opportunities for integration

- Proximity to the point-of-use to minimize losses in heat exchangers

- Operational scheduling—aligning process heat demand with solar production or thermal energy storage capacity

In regions with high solar irradiance, such as parts of Chile, Spain, and Australia, adoption potential is often greater, making ROI more attractive.

Selecting the Right Solar Thermal System

The choice of solar thermal collectors depends on temperature requirements and industrial applications. For low-temperature processes, flat plate or evacuated tube collectors are common. Medium-temperature needs up to 200°C can be met through advanced vacuum collectors, while high-temperature manufacturing, chemical synthesis, or distillation processes may require concentrated solar thermal technologies such as parabolic troughs or linear Fresnel reflectors.

Solar concentrators focus sunlight to achieve higher temperatures and enable solar steam generation for industries such as food processing, textiles, or metals. The integration pathway hinges on balancing technology capabilities with process heat optimization goals.

Integration and Operational Strategies

Integrating solar heat into existing operations involves coupling renewable thermal energy sources with conventional boilers or industrial heating loops. Hybrid systems can ensure consistent supply, using thermal energy storage or auxiliary heating during low irradiance periods.

Key integration strategies include:

- Direct heating—linking collectors to process heat exchangers

- Indirect heating—charging thermal storage tanks for later use

- Parallel operation—solar heating as a supplement to fossil-fired boilers

Advanced control systems can manage flow rates, optimize collector output, and maintain process temperatures. Process heat integration is often most viable when planned during equipment upgrades or plant design phases.

Financial Considerations and ROI

Capital expenditure remains a barrier for some operators; however, falling equipment costs, government incentives, and energy savings are driving adoption. Payback periods for industrial solar heating system design can range from 3 to 10 years depending on site conditions, fuel prices, and system scale.

Financial modeling should include:

- Installed cost per square meter of solar field

- Yearly fuel cost savings from solar energy for manufacturing

- Maintenance and operational expenses

- Revenue or credit from carbon reduction programs

According to NREL, high solar irradiance regions with strong policy support offer the shortest payback timelines, particularly for energy-intensive sectors such as food and beverage manufacturing.

Proven Success: Industrial Case Studies

Global examples demonstrate SHIP viability and scalability. The Codelco copper mine in Chile operates the world’s largest application, with a 39,300 m² collector field producing hot water for leaching processes. Breweries in Austria, Portugal, and Spain have adopted systems to provide hot water for brewing, cutting fuel costs while enhancing sustainability branding.

These projects highlight diverse industrial energy solutions—from high-temperature solar steam generation in mining to medium-temperature thermal solar applications in food and beverage manufacturing—delivering measurable energy efficiency gains.

Sunlit Success: Implementation Roadmap

For manufacturers considering industrial renewable energy investments, a staged roadmap is effective:

- Conduct a solar potential and thermal demand audit

- Select appropriate solar heating technology based on operating temperature

- Design the solar field and integration scheme

- Install collectors, heat exchangers, and control systems

- Implement commissioning and operator training

- Monitor system performance and optimize solar thermal efficiency

This pathway allows plants to align renewable thermal energy installations with production schedules and capital planning cycles.

Solar Horizons: Conclusion and Next Steps

As industrial sectors face tightening emissions regulations and volatile fuel prices, solar industrial applications offer a clear pathway toward cleaner, more resilient operations. Technologies are mature and in use across multiple continents, with market analyses projecting significant growth through mid-century.

The next step for companies lies in thorough feasibility analysis and strategic integration planning, ensuring that process heat demands are met efficiently and sustainably. With renewable energy systems increasingly central to manufacturing competitiveness, solar process heating represents not just an environmental choice, but a sound industrial sustainability and economic strategy.