Scaling Solar: Micro-Factory Models for Distributed PV Component Production

Bright Beginnings: Unpacking Micro-Factory Models

As the global solar industry races to meet ambitious renewable energy targets, a new manufacturing approach is emerging: the micro-factory. Compact, adaptable and tech-driven, these facilities are redefining distributed manufacturing by producing photovoltaic components close to where they’re installed. According to BMF 3D, micro-factories leverage lean manufacturing principles, minimize waste through just-in-time production, and enable rapid customization. For solar panel production, that means reduced supply chain dependency, faster deployment of systems, and enhanced local economic impact.

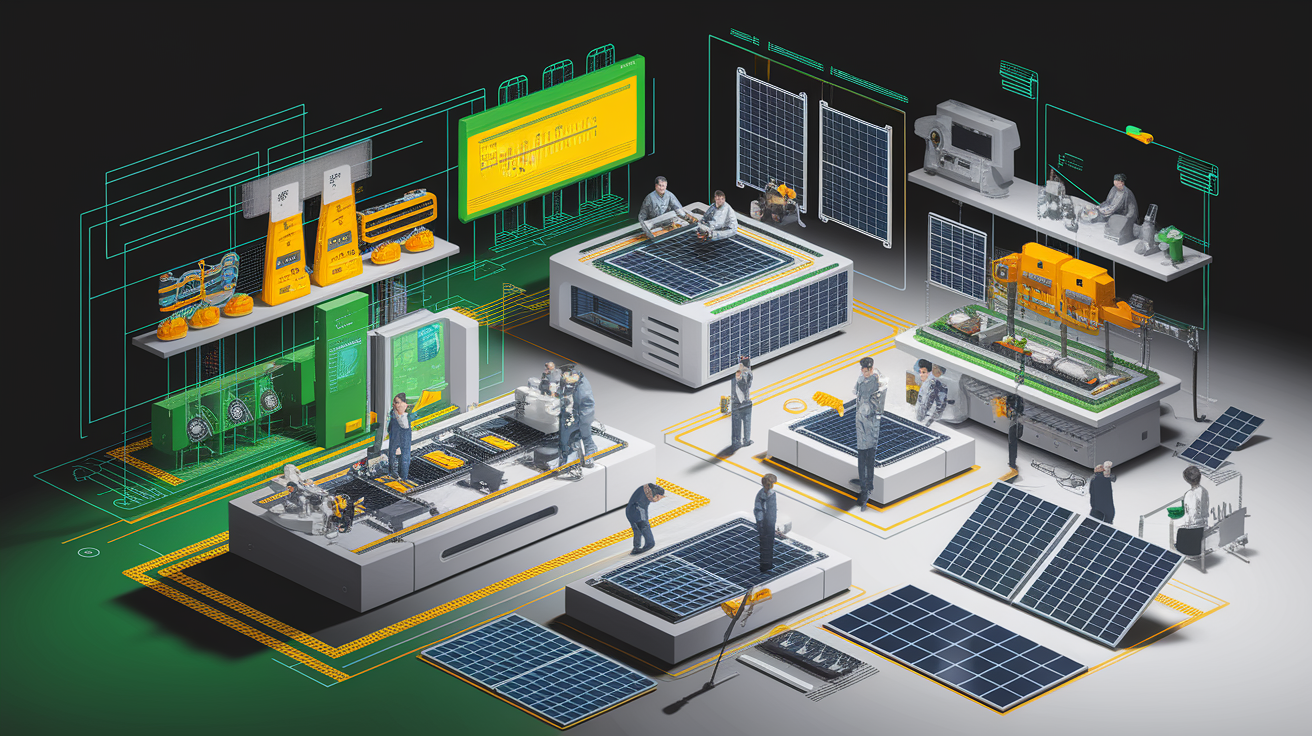

Core Concepts: Essentials of a PV Micro-Factory

In renewable energy manufacturing, a PV micro-factory differs from conventional gigafactories by focusing on small-scale, modular production lines. These sites typically feature:

- Automated assembly lines for solar cells, PV modules and solar inverters

- Additive manufacturing technologies for precision solar component fabrication

- Digital manufacturing tools including digital twins for design iteration and optimization

- Flexible manufacturing systems that adapt to market demand for customized solar solutions

- Lean, local production footprints aligned with sustainable manufacturing principles

The integration of Industry 4.0 technologies—automation, AI-driven quality control and IoT-enabled process monitoring—makes these small-footprint facilities competitive with traditional solar manufacturing plants.

Why Go Micro? Advantages for Distributed PV Production

Micro-factories can drastically improve supply chain optimization for distributed energy systems. In the solar sector, they allow on-demand production of PV modules, which reduces warehousing needs and lowers costs. Benefits cited by PV Magazine USA include:

- Rapid deployment compared to gigafactories

- Lower capital expenditure enabling wider market entry

- Community-level job creation and workforce development

- Environmental equity through localized production in underserved regions

- Support for the circular economy by reusing materials in solar component assembly

These advantages make micro-factory models a strategic fit for regions seeking to strengthen their renewable energy manufacturing base while cutting carbon footprints.

Roadblocks to Rooftops: Overcoming Implementation Challenges

While promising, deploying decentralized manufacturing in the PV sector is not without barriers. Connectivity and automation increase vulnerability to cyberattacks and data breaches, a challenge noted by BSR. Scaling micro-factories also demands skilled labor familiar with manufacturing automation tools, as well as regulatory coordination for safety and environmental compliance. Financing can be difficult due to smaller unit output compared to centralized plants. These hurdles require targeted solutions.

Mitigation efforts include robust cybersecurity protocols, workforce training in smart factory operations, and cooperative agreements between municipalities and manufacturers to streamline local permitting.

Blueprint for Success: Steps to Launch a PV Micro-Factory

For stakeholders interested in establishing small-scale PV module manufacturing facilities, industry experts outline a step-by-step approach:

- Assess Regional Demand: Analyze local solar installation targets and energy storage system integration needs.

- Select Site & Scale: Choose modular infrastructure to allow future expansion.

- Integrate Technology: Deploy additive manufacturing, automated assembly lines and IoT monitoring.

- Secure Supply Chains: Establish regional material sourcing to ensure resilience.

- Train Workforce: Implement continuous learning for evolving digital manufacturing processes.

- Launch & Iterate: Use on-demand production models to optimize efficiency and cost-effectiveness.

Local Lights On: Case Studies in Action

Across North America, PV micro-factory projects are proving scalable. In economically disadvantaged areas, The Comings Foundation reports facilities producing solar cells and modules locally, cutting transport emissions and creating direct employment. Meanwhile, regional manufacturing hubs in the Midwest are integrating green manufacturing methods and deploying energy storage systems alongside solar production to support grid stability.

In Canada, compact solar component assembly sites designed with modular production layouts have demonstrated that distributed PV manufacturing networks can rival centralized plants in output agility, especially for customized solar solutions that require short lead times.

Future Horizons: Scaling Local PV Manufacturing

Looking ahead, industry analysts suggest that scalable micro-factories could become a backbone of renewable energy manufacturing infrastructure. By harnessing manufacturing scalability techniques and expanding regional solar panel manufacturing hubs, the sector can meet growing demand more sustainably. Integration with distributed energy systems and local storage facilities will further increase resilience.

However, sustainability will hinge on continued collaboration. Manufacturers, governments and communities must jointly invest in secure, efficient and adaptive decentralized photovoltaic manufacturing systems. As PV Magazine USA notes, strengthening the solar supply chain through micro-factories is not just a technological upgrade—it’s a strategic shift toward a cleaner, more equitable energy future.