From Silicon to Solar: A Step-by-Step Guide to PV Module Manufacturing

Dawn of Solar Panels

Photovoltaic (PV) module manufacturing is a cornerstone of the renewable energy industry, transforming raw semiconductor materials into robust, high-performance solar panels. These modules combine 36 to 72 interconnected photovoltaic cells into a unified, weatherproof unit, serving as the essential building blocks of solar power systems. According to PV Manufacturing, encapsulation with advanced materials such as EVA film, tempered glass, and backsheet layers enables the modules to withstand decades of environmental exposure.

For solar panel assembly lines worldwide, the process is both a technical and logistical feat—balancing automated precision, quality assurance, and cost optimization. The entire production, from raw silicon to final delivery, can take several hours to days depending on capacity and automation levels.

Silicon to Cells

The journey begins with crystalline silicon—the industry’s dominant semiconductor due to its efficiency, stability, and scalability. Manufacturing starts with growing high-purity silicon ingots, often via the Czochralski process. These ingots are sliced into ultra-thin silicon wafers using precision saws. The wafers then undergo surface polishing, doping with elements like phosphorus or boron to form a p-n junction, and texturing to improve light capture.

As reported by Rayzon Solar, anti-reflective coatings are applied to enhance absorption, and each solar cell is tested for baseline efficiency before integration. These steps are crucial for ensuring optimal solar module efficiency throughout the photovoltaic production line.

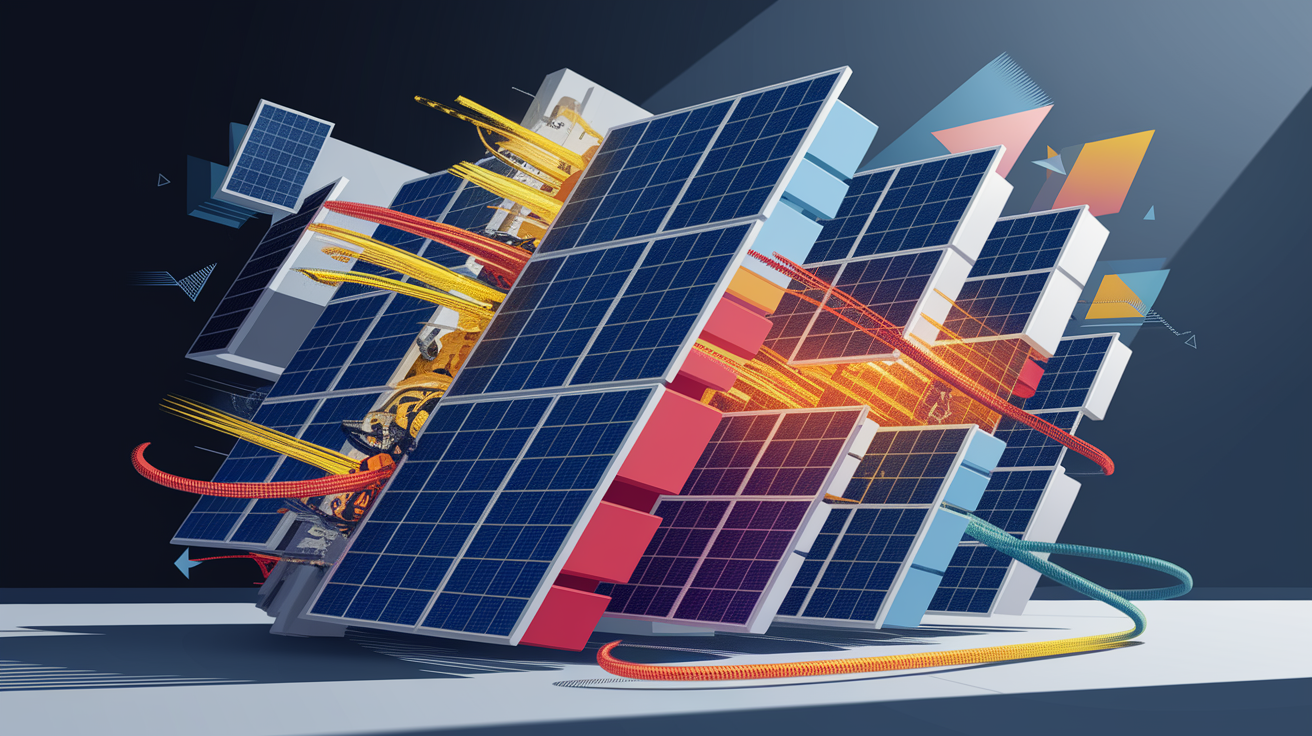

Cell to Module Assembly

In the cell stringing process, individual photovoltaic cells are soldered together using conductive ribbons in series, creating flexible strings that will form the heart of the module. Automated solar panel manufacturing equipment aligns these cell strings on a tempered glass substrate, layered with EVA encapsulation materials. The cell interconnection is secured through soldering bus ribbons, with bypass diodes integrated to prevent hot spot formation.

A backsheet material is added to insulate and protect the rear surface. This sandwich of glass, EVA, cells, and backsheet proceeds to the lamination process—subjected to carefully controlled temperature and pressure to create a sealed, durable unit. The laminated module is then fitted with an aluminum frame for rigidity and a junction box for electrical connections. This is a critical step in how photovoltaic modules are assembled, ensuring mechanical integrity and long-term environmental resistance as detailed in Ecoprogetti.

Ensuring Quality and Performance

Quality control testing is paramount in PV module production. Modules undergo electroluminescence imaging to detect micro-cracks or soldering defects invisible to the naked eye. Electrical testing includes flash testing to measure output under simulated sunlight, insulation resistance checks, and wet leakage current assessment. Mechanical load testing verifies the module’s ability to withstand wind and snow loads, while thermal cycling and humidity freeze testing simulate decades of weather exposure.

Additional protocols, such as UV exposure testing and hot spot endurance evaluation, confirm that encapsulation materials and bypass diode functionality meet international safety and performance standards. Sunway PV notes that early detection of defects in the solar module manufacturing process is critical to minimizing warranty claims and maintaining production yield.

Final Touches and Delivery

After passing quality tests, each module undergoes cleaning and final visual inspection before packaging. Protective corners are added to safeguard the aluminum frame during transport. Modules are often stacked with separator sheets and wrapped to prevent micro-abrasions on the glass or backsheet material.

Delivery logistics are planned carefully to match project timelines and minimize storage exposure. In global PV supply chains, this step often intersects with cost optimization strategies, where manufacturers balance warehouse inventory against just-in-time delivery models.

Sunset Summary

From raw silicon wafers to weatherproof encapsulated modules, PV manufacturing is a precise and multi-layered process that merges science, engineering, and industrial logistics. The step-by-step solar panel manufacturing process—silicon refinement, wafer preparation, solar cell fabrication, string assembly, lamination, and testing—ensures the reliable conversion of sunlight into electricity for decades.

Whether monocrystalline panels for maximum efficiency or polycrystalline modules for cost-effective scalability, the industry continues to innovate in materials, automation, and testing standards to improve performance and sustainability. For battery enthusiasts and renewable energy advocates, understanding the solar panel fabrication chain underscores the intersection of storage and generation, paving the way for a cleaner energy future.