Sun-Powered Efficiency: A Guide to Solar-Site Logistics & Supply Chain Optimization

Solar Logistics Illuminated

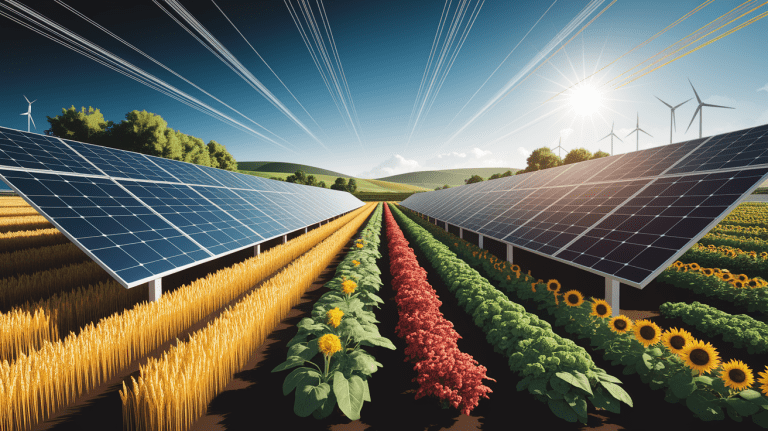

As solar panel installation and photovoltaic systems scale to meet global renewable energy targets, logistics optimization and supply chain management have become critical to project success. The solar supply chain spans sourcing raw materials, manufacturing solar equipment, transportation planning, warehouse management, and final-mile delivery. Many components, including solar panels, solar inverters, mounting systems, and electrical components, originate from manufacturing hubs in Asia, requiring careful handling during port drayage, intermodal transfers, and delivery to installation contractors for solar farm construction or other renewable energy projects.

Industry experts note that the high value and fragility of these materials, coupled with diverse geographic origins, place immense pressure on project management teams to coordinate transportation, storage solutions, and vendor relationships effectively. Missteps in logistics can result in cost overruns, installation timeline delays, and reduced efficiency in solar project delivery (Averitt, InfoLink).

Predicting Solar Needs: Demand Forecasting and Planning

Demand forecasting for solar equipment procurement is essential in aligning supply chain resources with construction scheduling. Through photovoltaic installation logistics management, companies can avoid bottlenecks associated with overstocking or shortages. Advanced analytics tools now integrate historical installation data, seasonal energy market fluctuations, and supplier lead times to produce accurate procurement planning models. This allows renewable energy project managers to stage inventory effectively while accommodating supplier relationships and mitigating the impact of volatile global trade conditions (Kuehne+Nagel).

Staging for Success: Site Preparation and Material Handling

Successful solar farm construction begins well before components arrive on site. Site preparation includes groundwork, staging areas for material handling, and safety management for installation contractors. Project coordination teams must map out precise unloading zones and secure construction materials storage with climate control where necessary. Specialized equipment transportation and mounting system handling procedures help maintain quality control, especially for delicate photovoltaic modules. Proper staging ensures installation efficiency once the build phase begins.

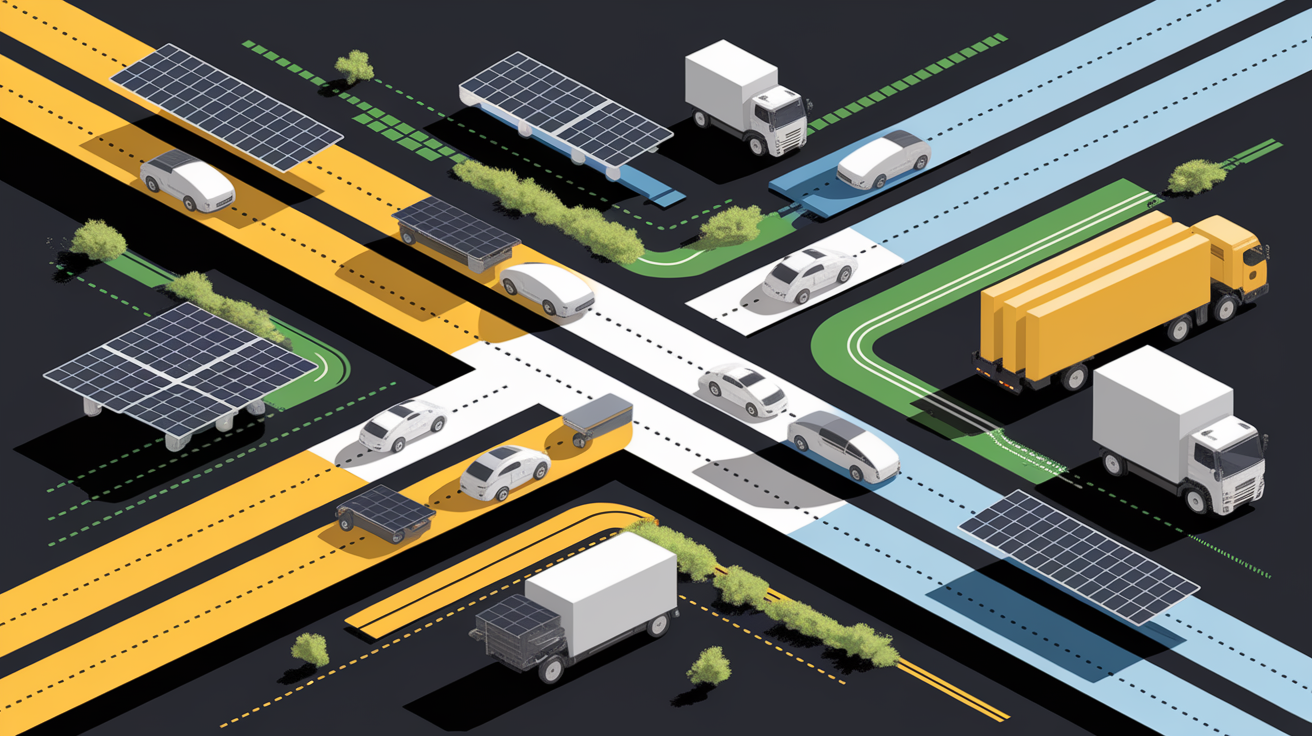

Smooth Transit: Transportation Strategies for Solar Components

Transportation planning for solar panels and related electrical components is a balancing act between cost optimization and timely delivery. Logistics providers use multimodal transport—combining sea freight for bulk solar equipment, air cargo for urgent materials, and land-based fleet management—for final-mile delivery. Route optimization software further reduces transit time and fuel consumption. In solar project procurement and logistics, risk management often involves securing backup carriers to counter possible delays due to port congestion or infrastructure issues (Averitt).

Inventory Radiance: Managing Stock and Warehousing

Warehouse management plays a pivotal role in maintaining solar project supply chain visibility. Distribution centers strategically located near solar industry hubs reduce transit distances and permit faster installation timelines. Climate-controlled storage protects sensitive solar equipment from humidity and temperature fluctuations, while digital inventory management systems offer real-time tracking for each photovoltaic module, inverter, or mounting system. End-to-end visibility improves resource allocation and supports precise delivery tracking for installation contractors.

Smart Rays: Leveraging Technology and Automation

Technology is transforming solar panel supply chain optimization strategies. Big Data tools analyze transportation routes, site preparation timelines, and inventory trends to inform proactive project coordination. Automation systems in warehouse handling, paired with IoT-enabled sensors, enhance quality control and reduce labor bottlenecks. AI-driven procurement planning algorithms help solar projects adjust dynamically to supply chain disruptions while prioritizing green supplier selection for sustainability compliance (Cal-Tek).

Weathering the Storm: Risk Management Strategies

Solar installation supply chain efficiency can be severely impacted by extreme weather events, permitting delays, and trade restrictions. Robust risk management involves building redundancies into project scheduling, diversifying supplier relationships, and developing contingency routes for equipment transportation. Compliance with regional environmental laws, ISO certifications, and proper documentation ensures smooth audits and uninterrupted market access (KanBo). Flexible project management strategies can accommodate sudden changes without jeopardizing installation efficiency.

Tracking Sunbeams: Performance Monitoring and Continuous Improvement

Performance monitoring in solar project delivery uses both quantitative metrics and qualitative assessment. Delivery tracking, warehouse turnover rates, installation timeline adherence, and equipment handling quality feed into continuous improvement models. Frequent project coordination meetings between logistics teams, suppliers, and installation contractors help identify bottlenecks and introduce corrective actions quickly. Over time, these insights build long-term resilience in solar farm logistics coordination services.

Powering Forward: The Path to Ongoing Optimization

Global trends in solar supply chain management are moving toward diversification of manufacturing sites, adoption of greener materials, and integration of smart logistics frameworks. As the industry targets terawatt-scale deployment, ongoing optimization strategies will rely on data-driven project management, sustainable equipment procurement, and collaborative vendor coordination. Aligning all stakeholders along a transparent and well-managed supply chain will be essential to meeting renewable energy expansion goals, while maintaining cost efficiency and quality assurance (U.S. Department of Energy).